The global population is

estimated to reach

9 billion by 2050

More than 50% of all the food

in the world is wasted

Poor agriculture practices

decreases diversity,

nutritions and soil quality

Biofuel production reduces

accessible land

for food production

Climate change effects

production through changing

whether conditions

90% of all fish stocks are

overfished or fully utilized

Our solution advantages

Preserve food taste, texture, and color

Our technologies maintain the sensory characteristics of food products throughout the drying, milling, storage, and distribution process. Preserving these qualities is important for ensuring that consumers receive high-quality products that meet their expectations.

Cost and energy efficient processes

We design and implement business operations that minimize costs and energy consumption while maximizing output and productivity. This approach will benefit businesses in several ways, including reducing expenses, increasing profitability, and improving sustainability.

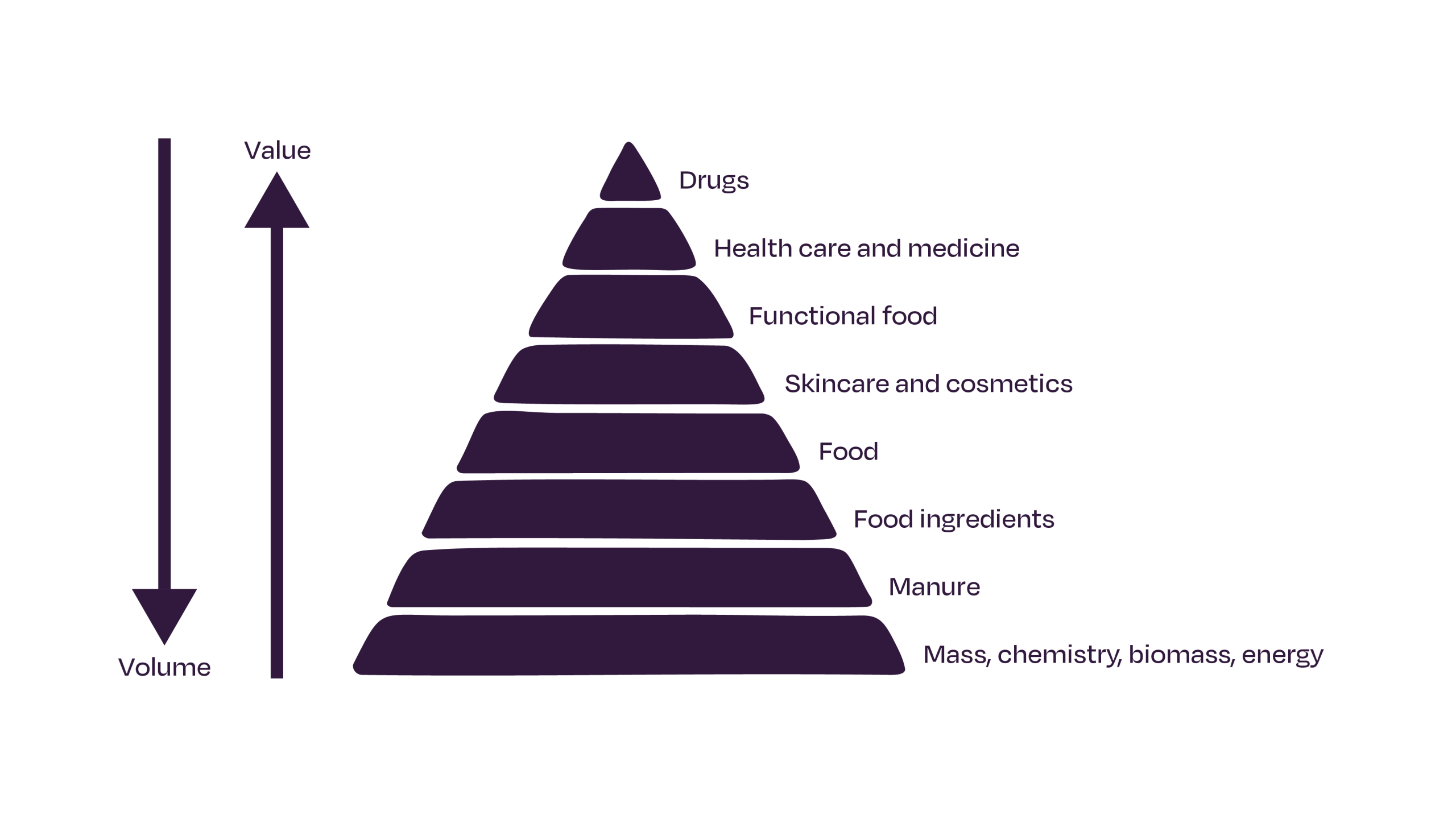

Capture value in your side streams

We target the waste materials produced in your business operations to leverage their value. By identifying these side streams and finding ways to utilize them, businesses can not only reduce waste and environmental impact but also create new revenue streams and cost savings.

Preserve the nutritional value

Our technologies ensure that food products retain their essential vitamins, minerals, and other nutrients throughout the drying, and milling process. This is important for maintaining the health and well-being of consumers and is especially critical for vulnerable populations, such as children and the elderly.

Technology

Patented drying technology, decreasing energy consumption > 90% compared to conventional methods. Patented micronizing technology, milling material without breaking cell structures.

This technology utilizes a unique process that involves heating the material being dried with hot air while also using a desiccant to absorb moisture from the air. By doing so, this technology is able to dry materials at much lower temperatures and with much less energy compared to traditional drying methods. This not only reduces energy consumption and costs but also helps preserve the quality of the materials being dried, as high temperatures can cause damage to some materials. This is particularly important for materials that contain sensitive compounds, such as vitamins, minerals, and antioxidants.

Traditional milling methods can damage or destroy these compounds, reducing the nutritional value of the material. However, this patented technology allows for the milling of materials without causing such damage, thereby preserving the nutritional value and other beneficial properties of the material.

Product & Application Area

Ongoing R&D Work

A. Exploitation of the market of vegetable

side stream

B. Seasonality and production structure

C. Capturing side streams in primary

production

D. Market size and how to market

upcycled products

We are partnering with Handelshogskolan and Chalmers to work with the best students on several research topics that will help us identify the best industry practices and sharpen our work.

The team

Anneli Andelén

Chair of the Board

Ola Ekman

Partner, Board Member and Growth Manager

Agneta Olsson

External Advisor

Illona Miglavs

External Advisor

Roger Wiklund

Partner and Board Member

Ruvini De Silva

Project Manager and Researcher

Johannes Larsson

Project Manager and Researcher

Sara Håkansson Maxence

Innovation & Food Business Developer